On Friday, October 7, we had a very inspiring session by Mr Uday Narang, head of the Anglian Omega Group and an evangelist for electric vehicles. Mr Narang spoke about the electric vehicle opportunity in India and how his company is contributing to sustainability and green living.

Here is the link to the video recording of the entire session.

About Mr Uday Narang

Mr Uday Narang is head of the Anglian Omega Group which includes the following:

Name |

Description |

Omega Bright Steel |

One of India's largest Bright Bar steel manufacturing companies. |

Yashdeep Automotive |

A leading manufacturer of high-quality machine components for engines as well as powertrains. |

OBSC Perfection |

An auto components manufacturer. |

ADM Technologies |

A packaging services company. |

Aditi Power Equipment |

High quality steel canopies for generator sets in India. |

Khel Now |

Social Platform connecting Sports Fans and Businesses. |

Omega Seiki and Omega Seiki Mobility |

Automotive components and EV manufacturing. |

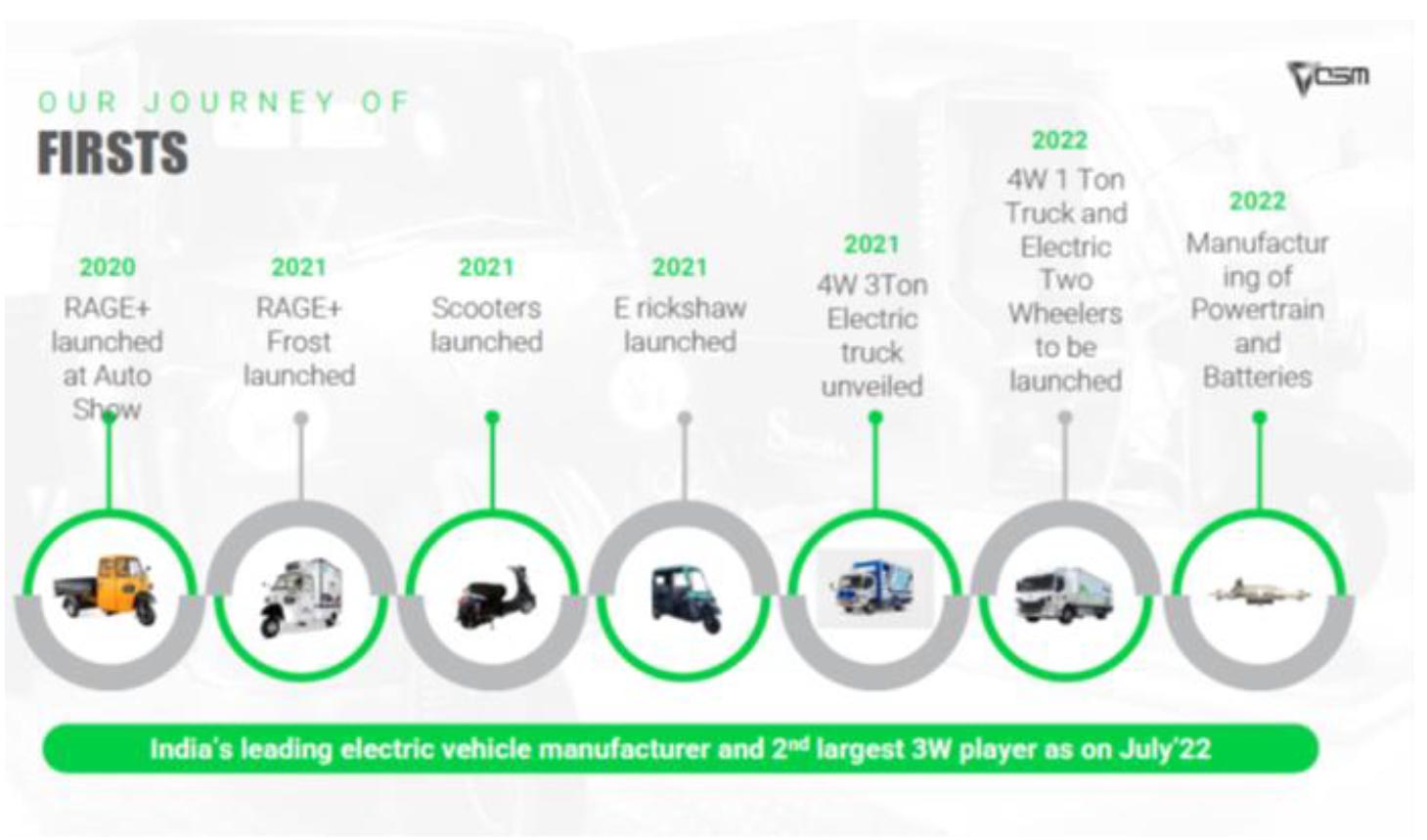

Mr. Narang came back to India in 2015. Realizing the problem of air pollution and the decreasing income of the drivers due to increasing fuel prices, he conceptualized and set up an Electric Vehicle (EV) company, Omega Seiki Mobility (OSM) in 2018. OSM’s focus is to create a clean ecosystem with eco-friendly, safe and congestion free mobility, with the help of data-driven, smart engineering.

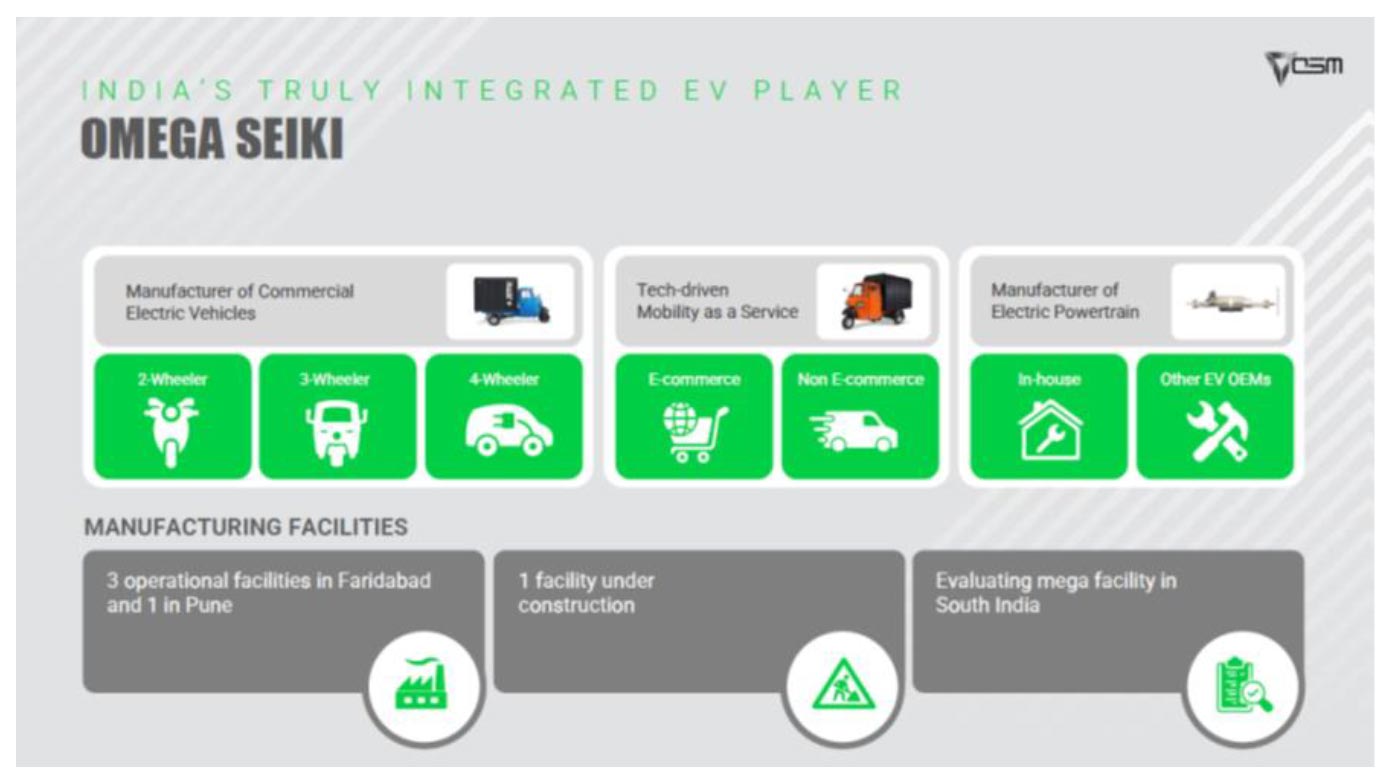

OSM has been growing its product line up and manufacturing footprint rapidly in India. The company is the first OEM to have two, three and four wheelers in its product portfolio. The company has set up large scale manufacturing facilities in Delhi NCR, Pune and is now looking to expand in Chennai. OSM is a leading last mile service provider under its brand "UNOXpress”. The company is currently running its fleet in 25 cities, doing more than 1,500,000 Km per month.

On why he entered the EV segment

Mr Narang jumped into the electric mobility segment, not to build a unicorn but to contribute in his own way to green energy and sustainability.

India is home to the 31 most polluted cities in the world. If our polluted air continues to be as bad as it is today, no amount of GDP growth (and achievements like a $ 10 trillion economy) will make us happy. Indeed, if we do not quickly change our style of living and embrace green technologies, our children will be lying in hospitals.

In a short span of 9 years, Mr Narang has already made an impact. His company has developed electric vehicles in multiple categories: two wheelers, three wheelers, four wheelers, tractors, 1-ton trucks.

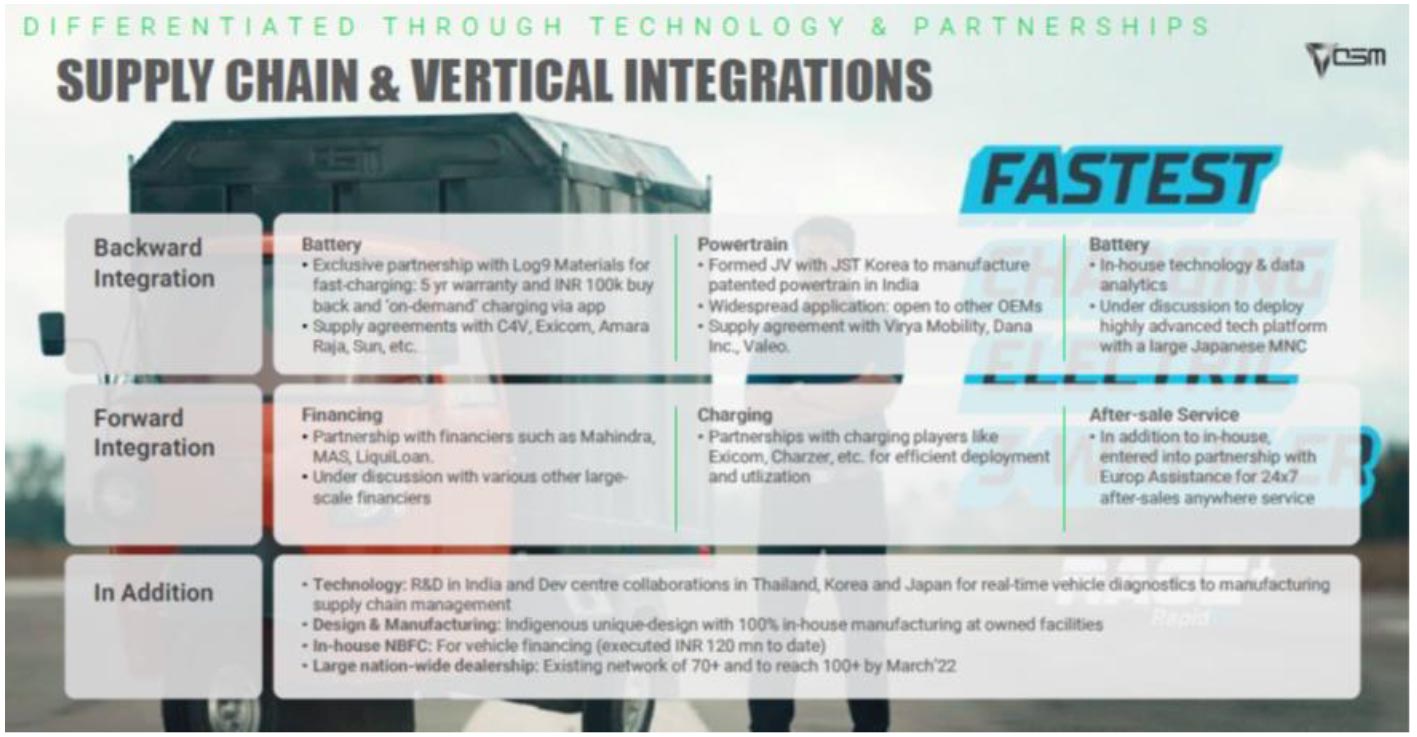

OSM is providing fast charging stations, building elegant two wheelers for rural India, making power trains and batteries and setting up a Technology centre. OSM is also exporting EVs in a big way. It has set up multiple facilities across the country. Mr Narang believes in collaboration and has joint ventures all over the world. Today, OSM has a well-oiled supply chain.

On the EV opportunity

Mr Narang feels that instead of saying the future is electric, we must start accepting that the present is electric. The EV market in India has witnessed a sharp spike in FY22 with more people shifting from internal combustion engine (ICE) vehicles to EVs of various kinds. The number of electric vehicles sold in the country has increased from just 18,000 in 2015 to over 6.6 million in 2021. EV sales are expected to touch 10 lakh units in 2022 – a growth of 327% over 2021. High-speed electric two wheelers recorded a 425% growth in sales in 2021. Total sales will reach 300-400 million vehicles by 2030.

The two-wheeler market is expected to be 30% electric in the next 4-5 years. 51.5% of three wheelers are already electric. Electric four wheelers will see 30% adoption by 2030. Cargo vehicles which contribute most to the pollution are also embracing EV technology.

The national and state governments are doing their bit to promote EVs. As many as 15 states have announced their EV policies. The government has introduced the Rs 10,000 Cr FAME II program which offers a 15%-20% subsidy on EV purchase. Besides, there is also exemption of road tax and permit. The government has also launched the Rs 18,000 Cr PLI scheme to manufacturers.

As Mr Narang put it, the trailer has started, and the movie has not begun. There are plenty of opportunities to take part in the EV ecosystem.

On the need for financing

The biggest issue facing the industry is financing. Many of the customers require financing. Current government policies are focused on the supply side. But without financing, the demand cannot take off.

Banks for some reason have been unwilling to lend. Their caution is difficult to understand as the technology is rapidly maturing and already 6-year warranties are being given on EVs. While NBFCs are providing loans, their interest rates of 18-21% are way too high. The public sector banks must jump in.

Inclusion of EVs for priority sector lending is key. This will provide banks another avenue to meet their targets for this sector. Non Banking finance companies will be able to access greater EV finance from banks that wish to leverage these institutions’ ability to reach far flung areas and high-risk borrowers. The move will also encourage banks to improve their understanding of EV technology and policy.

On the opportunities in rural India

Cities do not constitute the real India. We must take care of rural India as that is where the big opportunity lies. We must encourage rural people to stay in the villages and make a reasonable living rather than come to the cities and struggle to meet their expenses. We must make EVs affordable in rural India. The Teslas which cost Rs 60 lakhs are not the kind of vehicle that we need in our country.

There are already signs that EVs are taking off in rural India. Statistics from Vahan (a data repository of all vehicles registered in the country), reveal that the contribution of the top 10 districts in nationwide sales of electric cars and three wheelers dropped from 55-60% in fiscal 2021 to 25-30% in fiscal 2022. For two wheelers, it declined from 40-45% to 15-20%. The gaps are being filled up by smaller towns and rural India.

Around 70% of the country’s population is represented by rural India. But public transport and accessibility remain a challenge in many villages. No doubt, many households have the regular petrol-powered two wheelers. But then, petrol prices are rising and petrol pumps are far from many in fringe areas. This is where EVs fit in, and the timing seems to be good. Rural India is getting electrified. With improving power supply, charging these vehicles is not a distant dream for rural riders. Solar panels are gradually becoming a regular feature on rural rooftops.

In rural India, mostly pick-up trucks and tractors are used for commuting. Many of these vehicles are old and not very efficient in terms of fuel usage. To that extent, EVs may have found a ready market in the rural belt.

The pandemic has led to the expansion of digital shopping to include rural consumers. EVs can enable last-mile connectivity. What is more, electric bikes do not require a driving licence, making the process of owning one hassle-free.

On the importance of Batteries

Batteries are the core of an EV. We must improve the quality of batteries. Many Indian EV manufacturers are importing poor quality batteries from China as the prices are low. But in the process, they are compromising on quality and safety. This is unfortunate and reflects a lack of responsibility. 99% of the safety incidents (like explosions) are in the case of two wheelers.

Manufacturers must take a long-term view and focus on the total cost of ownership (initial cost, maintenance, warranties, etc) rather than look at the price. Testing should be done painstakingly under different conditions: heat, cold, rain. Omega on its part, works with only the best battery manufacturers who have a 10-year track record.

On recycling

Like China, India has a major EV growth market and can depend on a reliable supply of end-of-life batteries in the future. But unlike China, India does not have global supply chains for primary materials such as lithium and cobalt. So recycling is needed for India to become a large-scale EV battery manufacturer.

Just 94,000 metric tons of lithium-ion batteries (LIBs) were recycled globally in 2019, most of them from portable consumer electronics. In the next decade, however, EV batteries will start flooding the end-of-life battery market.

China has specific guidelines on removing, discharging, disassembling, and storing used EV lithium-ion batteries. But the other major players—i.e., the United States, Europe, and Japan—still do not have a regulatory framework that would facilitate profitable recycling.

The number of patents in EV battery recycling has increased dramatically in the last 10 years, showing the potential for innovation. With the right incentives and policy framework, India can leapfrog some EV battery recycling barriers and become a major player within the next decade. The potential is huge, with a global market expected to surge to 705,000 end-of-life LIBs (lithium ion batteries) by 2025 and to 9 million by 2040—most of which will be EV LIBs.

The initial stages of battery recycling require a lot of manual labour. Here, India has an advantage compared to other major players with a large population and lower labour costs compared to Western countries and China.

Q&A

On the importance of charging stations

EVs need a strong eco system and charging stations should be on top of the agenda. In 2021, we had only 950 charging stations compared to 300,000 in China.

We should do away with jugaad and instead embrace a long-term vision. We can all contribute in this regard. Every residential block, kirana store and supermarket should think of setting up a charging station. Not only will this be a great contribution to building a green India but also there is a lot of money to be made in the process.

On the importance of customer orientation

Customer orientation is important. The vehicles should run safely even on waterlogged roads without the danger of short-circuiting. Many customers overload the vehicles. So, we must design them in such a way that they are sturdy and can handle this extra weight.

As technology continues to improve over time, we can expect customers to get more and more value in the form of better power trains, batteries and more affordable pricing. Seeing the success of EVs, insurance companies are also jumping in.

We must bring down the costs of manufacturing EVs to make them affordable to the common man. Growing scale and improvements in technology will facilitate this process.

We must provide more options to customers-range, fast charging, pay per hour, etc.

On what BSchool graduates should do

Instead of doing a safe job, BSchool Grads should jump in and try to build their own companies. They must believe in themselves, work hard and not cut corners. They should strive to achieve their dreams. They must align with people and be committed to teamwork. With exciting opportunities around, it is possible that their venture might become the next unicorn. Mr Narang is ready to work with youngsters who have good ideas and help them to take their product to the market.

Other points

We must start making EVs in a big way using JVs where needed. Vietnam’s VinFast has demonstrated this. Established in 2017, it is the first Vietnamese car brand to expand into global markets as well as the first to expand into producing EVs such as electric cars and electric scooters. Indian engineers are behind the success of this company. Why can’t we leverage our engineering expertise for our own benefit?

We must increase the use of clean energy. Every home should be running on solar energy. We need all forms of clean energy and not just EVs. We also need blue energy (hydrogen). OSM’s Technology centre is working on various green technologies.