An evening with Dr Kishore Indukuri

Introduction

On November 9, we had the 170th session of ICFAI’s WiseViews Leadership Conversation series featuring Dr. Kishore Indukuri, the founder of Sid’s Farm. Dr Kishore narrated his inspiring journey and how he gave up his comfortable corporate life at Intel in the US for a fulfilling venture in dairy farming. Dr Kishore also explained the challenges involved in building a premium direct-to-consumer dairy brand.

About Dr. Kishore Indukuri

Dr. Kishore Indukuri is the Founder and Managing Director of Sid’s Farm Private Limited, a pioneering company dedicated to delivering pure, unadulterated milk to households across Hyderabad and Bengaluru.

After earning a bachelor’s degree in chemistry from IIT Kharagpur, Dr. Indukuri moved to the United States, where he obtained a Master’s and Ph.D. in Polymer Science & Engineering from the University of Massachusetts, Amherst. He then joined Intel Corporation in Chandler, Arizona, where he held roles such as Quality & Reliability Engineer, Senior Process Engineer, and Sr. Materials Engineer for around six years.

In 2013, Dr. Indukuri returned to India to pursue his entrepreneurial passion. He founded Sid’s Farm with the mission of providing families with pure, unadulterated milk. Sid’s Farm started with a small dairy farm and just 20 cows. It has since grown into a 400+ member team serving over 50,000 households daily and supporting the livelihoods of more than 4,500 farmers. The company recently raised $10 million in Series A funding, setting the stage for further expansion.

Dr. Indukuri’s commitment to quality is unwavering. Sid’s Farm is known for its antibiotic-free, hormone-free, and preservative-free milk, ensuring the highest standards through rigorous testing and promoting transparency and sustainability. Sid’s Farm is poised to make a significant impact on the Indian dairy industry, which is projected to reach nearly ₹50,000 billion by 2032.

Entering the dairy business

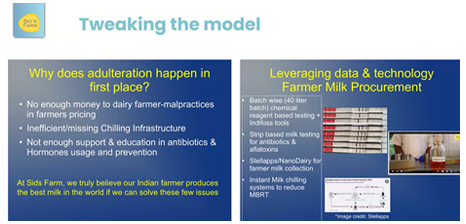

When he resigned from Intel and came to India, Dr Kishore began to look seriously at the dairy sector. Since Independence, thanks to the work of Amul and others, the problem of quantity had been solved. India had enough milk. But the problem of quality remained. Occasionally, one would hear of customers complaining about adulterated milk. There were reports of antibiotics misuse. There was no premium milk available in the market.

Sid’s Farm began as a promise from a parent to his son to produce the best milk possible. The idea was to produce pure 100% tested milk which did not have any antibiotics, hormones, preservatives or thickeners. Also, by chilling the milk at the source to 4 degrees Celsius, its life could be naturally extended to 7-10 days. "In fact this is the only right way to preserve milk" mentioned Dr. Indukuri.

Customers

Consumer education through weekly open houses aimed at increasing consumer awareness and building customer loyalty. Customers could see for themselves, the operations and how the lab worked. The milk would be delivered to customers through an app at their doorstep. When Sid’s Farm began operations, the direct-to-consumer concept did not exist.

Farmers

Dr Kishore considered farmers to be the greatest asset. So, Sid’s Farm paid a fair price to farmers. It also tried to help the farmers in various ways.

Challenges

Dr Kishore started his venture on a leased farm with 20 cows. He did not know how to select a cow, nor did he get any good guidance from so called experts. Only after the operations began, Dr Kishore realized how tough the business was. They made a loss against a projected margin of 30%. The projected capital recovery period of 1.7 years was way off the mark.

365 days a year, cows had to be milked 2 times a day everyday no matter what. There were labour/animal health/productivity issues.

In 2013, the prices for cow milk were abnormally low at Rs 13-15 /per litre in bulk market. The cost of production was Rs 30. They had to sell milk on their own to survive. So, they started selling milk direct to customers at Rs 44/litre.

The team would milk the cows, manually pack the milk and have the milk reach customers by 6 in the morning. From stainless steel, they moved to plastic pouches. As demand increased, they moved from hand to foot operated packaging machines and finally invested in an automatic packaging machine.

The milk had to reach customers by 6 in the morning. So, as the volumes rose, the cow milking had to be done earlier and earlier. At one point, they were waking up at 1: 30 am. The team realized that this was not sustainable. So, after about one and a half years, they invested in a mini-pasteurization facility at the farm.

Meanwhile, all of Dr Kishore’s savings had evaporated. He had only Rs 10000 in the bank account. But the team did not give up. They kept executing and started tweaking the business model.

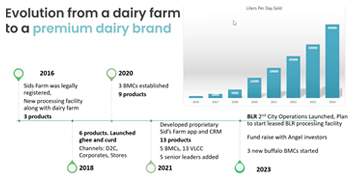

Evolution of a premium diary brand

Sid’s Farm has come a long way since it was registered in 2016. In 2018, ghee and curd began to be offered. The company today has operations in Bangalore and Hyderabad. It sells 44,000 litres of milk per day and offers 13 products. During the Q&A, Dr Kishore mentioned that Sid’s offers three types of milk: cross breed cow, buffalo, desi cow. This is in line with customer needs.

Each metropolis consumes around 50,00,000 litres of milk per day. The premium segment is about 10% or 500,000 litres per day. So, there is a huge market opportunity.

Value chain

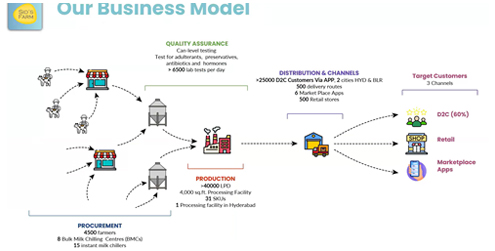

Dr Kishore once had an interesting discussion with a research scholar from Germany. He later became a professor at IIM Ahmedabad and invited him to give a talk on the value chain of Sid’s Farm. Dr Kishore had not heard the term value chain before. As he prepared for the talk, he realized that there was a need for clarity about Sid’s core area of expertise. They were in milk procurement, processing, logistics, testing and marketing. (See figure above.) Where should they concentrate? Where could they leverage others’ help?

Testing

One of Sid’s Farm’s core competencies is testing. When the operations began, Dr Kishore would answer all customer calls himself between 6 am and 10 am. Quite a few of the questions revolved around how Sid’s was ensuring quality. Dr Kishore realized that much more had to be done to ensure quality. There was a need for processes to deliver what was being promised.

More than 99.5% of the farmers are honest. But the few who are dishonest can create mistrust and doubt in the minds of customers. This is where testing becomes critical.

The most common testing machine is the ultrasound sensor. It can test for thickness but cannot diagnose why the milk is thick or thin. Dr Kishore started using NDDB kits. These cost Rs 4000 and got over in a day. To cut costs, Dr Kishore decided to put his knowledge of chemistry to good use. He bought chemicals locally and leveraged the FSSAI (Food, Safety and Standards Authority of India) website to put together a testing kit. Today testing is done for urea, sugar, salt, melamine, starch, hydrogen peroxide, etc. In fact, Sid’s spends Rs 7 lakhs a month only on antibiotics testing.

During the Q&A, Dr Kishore mentioned that with experience, customers can check for adulteration based on taste and smell. But thorough testing can be done only in the lab. Currently the kits are expensive. But hopefully, over time, the costs will come down.

Each day, Sid’s keeps some buffer milk. This is to ensure that even if some milk fails in the tests, there is enough extra milk that can still be delivered to customers without any delay. Of course, this adds to the cost of operations.

Recognitions

Sid’s Farm has received various recognitions:

- MANAGE-Samunnati Best Agriculture Startup Award 2022 for Telangana State

- TV9-SAP Agri Start up Award 2022 & Winner of 3 D2C startup Awards in 2023

- Recognized as one of the top 3 players in the premium dairy space in India.

The road ahead

India’s large vegetarian population of about 500 million is heavily dependent on milk for its nutritional requirements. As mentioned, each Indian metropolis consumes 50 lakh litres per day on average. The mass premium/fresh/org milk market is 10% of overall milk market. Only 30% of the needs are met by the organized sector. India’s dairy market is estimated at $ 150 bn and is growing at a CAGR of 12%. Value added products like paneer, ghee, curd, make up 35% of the market. This segment is growing at 30% per annum. In short, the opportunities for Sid’s Farm are exciting, particularly with the mobilization of fresh capital.

Q&A

Sid’s offers premium milk. But there is a distinct value proposition- no antibiotics, hormones or preservatives. That is why customers are prepared to pay an additional Rs 900-1000 per month.

When it comes to products too, Sid’s does not take short cuts. The company grinds spices and curry leaves for butter milk even though this takes more time and is more expensive. The idea is to deliver clean natural products to customers.

The brand has grown organically through word of mouth. Customer loyalty has strengthened over time. When Sid’s once raised prices from Rs 44 to 55 per litre, the customers did not defect. Dr Kishore feels that it is all about being transparent with customers. The lesson is that pricing is a process of discovery. When customers trust a brand, there is greater pricing flexibility.

How does Sid’s compare with Amul? Amul is a huge player with breadth and scale. Sid’s is still a small player, but it is competing with depth and total involvement in delivering value to customers.

Sid’s does not view competitors as threats. Rather, it tries to learn from competitors and is focused on delivering value to customers.

Sid’s Farm is divided functionally into different groups: procurement, production and processing, lab, logistics, marketing and human resources.

The goal of Sid’s is to help create Farm-preneurs by supporting farmers in raising the required capital and providing them with the necessary knowledge and services to run their own dairy farm. Sid’s also provides important services (Veterinary, Banking & Finances, Feed Management, and other services) at minimal or no cost and offers a stable purchase rate for milk across all seasons. These farmers supply their milk exclusively to Sid’s Farm.

There are three company owned model dairy farms at Sid’s procurement zones. These model farms showcase viability and scale to farmers to setup franchisee dairy farms.

Sid’s works closely with farmers to make them succeed. Each farmer is different in terms of water availability, grass availability, etc. The objective is to enable the farmer to make a profit of Rs 5 -10 per Liter. Then they will be able to generate a good income. Sid’s works on all fronts to help farmers to become profitable, feed, genetics, pricing, etc. Currently Sid’s is working with 50 farmers. Some farmers are already profitable.

Cattle feed is a critical success factor. Delivering crude protein through grassis cheaper compared to dhana (concentrated protein). It makes sense to provide as much as crude protein as possible through growing different green grasses. It helps to have the grass ready 4 months before setting up the dairy farm. This ensures the cattle have enough to eat.

Milk is a good source of nutrition be it from a buffalo or a cow. Both cow’s milk and buffalo’s milk have what a baby needs. We can consume whatever we are comfortable with. There is no hard and fast rule. Cows are more agile than buffalos. So, there is an argument that this quality may be imbibed by consumers.If buffalo milk is very thick, it can always be diluted with a little water and given to children.

Dairy is a low margin business. An EBIDTA margin of 10-12% is very good. Typically, milk yields very low margins of 2-5%. The products offer higher margins. So, the blended margin is around 10-12%.

The best way to enter the business is to understand the market. Before making heavy investments in production facilities, we should work with a farmer and try to sell his milk. If we can figure out how to sell, other parts of the business will fall in place. It is all about identifying a customer segment and being clear about the value proposition.

The glass transition temperature is an important concept in materials science. At this temperature, glass softens, becomes like rubber and mixes with the material being stored. This is about 1000 degrees Celsius. At room temperature or lower, the risk of contamination in case of glass containers is negligible.

Reusable glass bottles may seem to be safer and more environment friendly than plastic pouches. But it takes 650 g of glass to contain 1 litre of milk against the 3 g of plastic. So plastic is less transportation intensive. (As transportation uses up crude oil, heavier the weight being transported, more the use of crude oil. Please remember, crude oil is what is used to make plastic).

The glass transition temperature is an important concept in materials science. At this temperature, glass softens, becomes like rubber and mixes with the material being stored. This is about 1000 degrees Celsius for glass. At room temperature or lower, the risk of contamination in case of glass containers is negligible.

In this regard, glass is superior to plastic. But if we chill the milk and pour it into plastic pouches, , it is close to a glass, especially if you are cold filling milk. We fill milk at 2-3 C in our packing lines at Sid's Farm and hence the risk of contamination is low. However, we should never pour hot milk into a plastic container.

In case of Desi cows, the farms are large. The chilling centres are located at the farm. There are also 2 central chilling centres for hybrid cow milk. In addition, for the farther villages, there are 15 village level chilling centres. In the villages, power may sometimes be available only for four hours.. Ideally every farm must have its own chilling station.

Dr Kishore believes that more than his technical and process expertise, it is people management that is his forte. He has been nice and kind to people. People have paid back many times more. Once there was a labour shortage. The villagers jumped in and helped to milk the cows even before milking their own cows. That is what happens when we are nice and respectful towards people.

Dr Kishore has also been able to build a great team. He has attracted people with a great attitude: the ability to take a lot of responsibility and operate with the founder’s mindset. Most of his team members are from outside the dairy industry. They have brought valuable outsider perspectives. (For example, one of them is from GSK and another from Mercedes Benz.)

Milk consists of water, fats, carbohydrates, vitamins and proteins along with bacteria. In probiotic milk and yoghurts, the objective is to increase the multiplier effect. Probiotic fermented milks and yoghurts are acidified and fermented by viable bacteria resulting in a thicker product with a longer shelf life. They are a good source of calcium, phosphorus, potassium, vitamin A, vitamin B2, and vitamin B12. They also deliver high biological value proteins and essential fatty acids. There is growing evidence that yoghurt and fermented milk consumption result in several health advantages. With Indians starting to consume more proteins, there is a growing demand for such products. According to Ayurveda, curd and butter milk may have even more nutrition value than milk.

This is an emerging concept. The main motivation is to prevent cruelty to animals. If we can take care of animals, there may not be any need for plant-based milk. The key to taking care of animals is to keep the farm size small so that there is a manageable number of animals.